Hero banner custom title

Recycled glass in concrete

3 min

Cities are using more and more concrete and are also generating huge amounts of glass waste. Incorporating glass waste into concrete would both divert it from landfills and reduce our CO2 emissions.

On the one hand we have concrete which causes pollution, in particular because of the cement used in its composition. And on the other hand we have glass waste, which can be completely recycled using what is a complex and costly process... So what if the glass were put into the concrete? This is the solution proposed by the Ellen MacArthur Foundation and its partners in a case study published in October 2016.

Concrete is one of the most widely used building materials in the world. In the United States, where the study was carried out, 600 million tonnes of concrete were produced in 2015. But it is also one of the materials with the greatest environmental impact, notably because of the cement used to make it. Although it makes up only 15% of concrete, cement is responsible for 96% of its CO2 emissions; 1 tonne of cement is equivalent to 1 tonne of CO2.

The 90 million tonnes of cement produced in 2015 in the United States therefore generated the equivalent of the annual emissions of 20 million cars!

To reduce its carbon footprint, the concrete industry began using two main substitutes for cement: fly ash, generated during coal combustion, and slag, a byproduct of steel manufacturing. These substitutes reduce CO2 emissions by 25 to 40% per tonne of concrete, improve durability, and reduce costs.

Glass is expensive to recycle

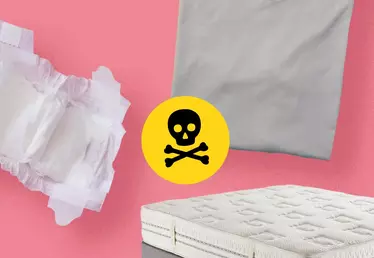

But these replacements are not a viable solution. First because they contain heavy metals, in particular mercury, which make them potentially toxic, and second because it means producers and users are still dependent on fossil fuels: "As more and more companies try to reduce their carbon footprint and use renewable energy, the use of by-products of fossil fuels in their buildings is increasingly seen as counter-intuitive and contradictory," writes the Ellen MacArthur Foundation's report.

At the same time, dealing with glass waste is increasingly problematic. Americans don’t manage to reuse their post-consumer glass - 11 million tonnes a year. Only one third is recycled, with the rest going straight into landfills. Although glass is 100% recyclable, the study says that an increasing number of American cities are abandoning their recycling programs, mainly for financial reasons: sorting glass is complex and costly, and it is a challenge to find effective end markets.

Pilot projects

The solution therefore seems obvious - incorporate used glass, ground into a powder, into concrete to replace some of the cement or its substitutes. The case study refers to pilot projects (in Montreal, New York, and Googleplex in Mountain View) that have demonstrated the technical viability of such an approach, and which would reduce the carbon footprint of concrete by between 20% and 40%. According to the Ellen MacArthur Foundation, grinding glass requires little energy and emits 18 kg of CO2 per tonne of glass (compared to 201 kg CO2 per tonne for fly ash).

There’s just one fly in the ointment; using powdered glass would have a significant financial impact - the Ellen MacArthur Foundation believes that it could mean a 2% to 5% increase in the price of concrete…